HVAC+R for Marine Facilities

The HVAC+R plants on vessels play a vital part in carrying refrigerated cargo and provisions for the crew on board. In reefer ships the temperature of the perishable or temperature sensitive cargo such as food chemical, or liquefied gas, is controlled by the refrigeration plant of the ship. The same plant or a smaller unit can be used for maintaining the temperature of different provision rooms carrying food stuffs for crew members.

The HVAC+R plants on vessels play a vital part in carrying refrigerated cargo and provisions for the crew on board. In reefer ships the temperature of the perishable or temperature sensitive cargo such as food chemical, or liquefied gas, is controlled by the refrigeration plant of the ship. The same plant or a smaller unit can be used for maintaining the temperature of different provision rooms carrying food stuffs for crew members.

A ship air conditioning and refrigeration system plays a major role in the comfort of passengers and crew and when it comes to the quality of the transported goods. The onboard AC system allows the crew to carry out their daily tasks in a comfortable environment

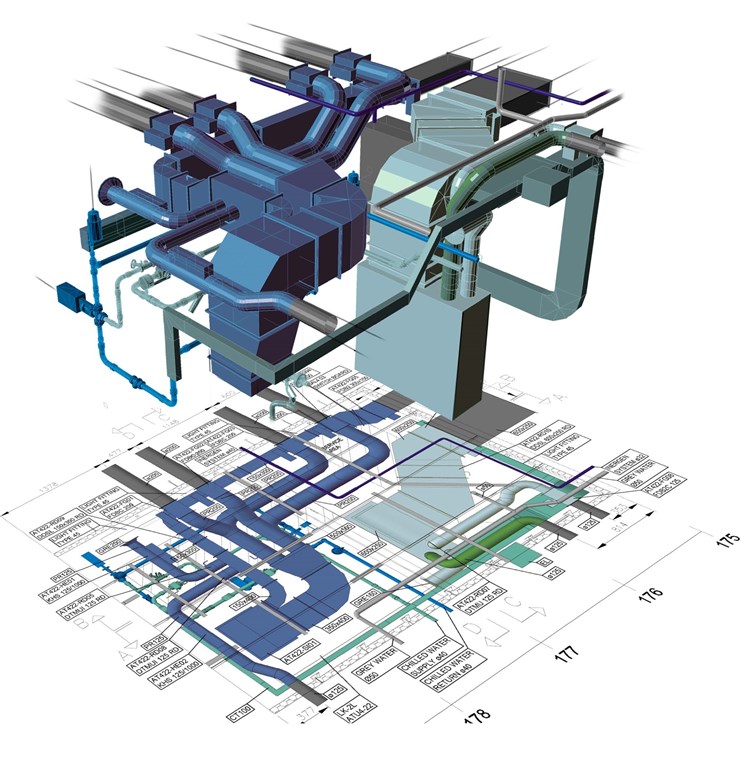

HVAC systems are critical for ensuring the safety and comfort of crew members and passengers. Getting HVAC systems right can improve both energy requirements and internal space utilization. Reduce design time and energy consumption, improve production quality, and maximize available internal space with our experience for designing HVAC equipment and systems for ships.

Today’s vessel operators are able to take advantage of modern heating and cooling capabilities to support crew well-being and provide ideal temperatures for sensitive electronics and other onboard systems. HVAC manufacturers are responding to ongoing pressure from vessel builders to develop durable and robust systems that are smaller, lighter, quieter, and provide higher capacity and efficiency.

Large complex HVAC projects in the marine industries are fraught with numerous challenges related to health and safety, logistics, economics, quality assurance and overall performance. Maximize HVAC productivity and construction quality with our next-gen software for designing HVAC equipment and systems for ships structures. Improve total enterprise productivity through the seamless integration with digital manufacturing solutions to ensure optimal manufacturing and assembly. Design, size and evaluate the performance of HVAC system architectures to deliver safer, greener and more comfortable ships, fast

The main purpose of ship's HVAC+R plant:

1. To avoid any damage to the cargo or perishable material so that

the cargo in transported in good and healthy condition.

2. Refrigeration prevents growth of microorganisms, oxidation, fermentation and drying out of cargo etc.

3.Occupants’ survival

4. Continuation of the specific activities carried out in these structures

What can HVAC do?

1. Maintain acceptable working and living environment for personnel and for

equipment.

• Offshore facilities are high in humidity, which needs to be controlled to

comfortable levels of 50 ± 5%.

• Comfort temperature range is 75±2°F and low temperature may be required

where sensitive equipment is placed. The temperatures are generally not

required to exceed 40°C in the electrical substations.

2. Provide air filtration to control airborne particles, dust and toxic odours. The

filtration for off-shore facilities may include the activated carbon and chemical

filtration.

3. Provide dilution ventilation

• To maintain an atmosphere where the gas/air mixture is kept below lower

explosion limit (LEL) during normal operation.

• To reduce the risk from build-up of potentially explosive / toxic gases within

these spaces.

4. Maintain room pressure (delta P) – space pressurization per the area

classification.

• To prevent smoke spreading and keep enclosed escape ways free of smoke

in case of fire.

• To prevent ingress of potentially explosive / toxic gas-air mixtures into nonhazardous

areas, electrical switch rooms and equipment rooms.

What HVAC can’t do?

• HVAC systems are not intended to prevent the catastrophic events such as

release of toxic and/or hazardous gases.

• HVAC can not compensate of its own, for the intrinsic safety design features

such as structural stability, coatings, area segregati