MAPNA Drilling Company

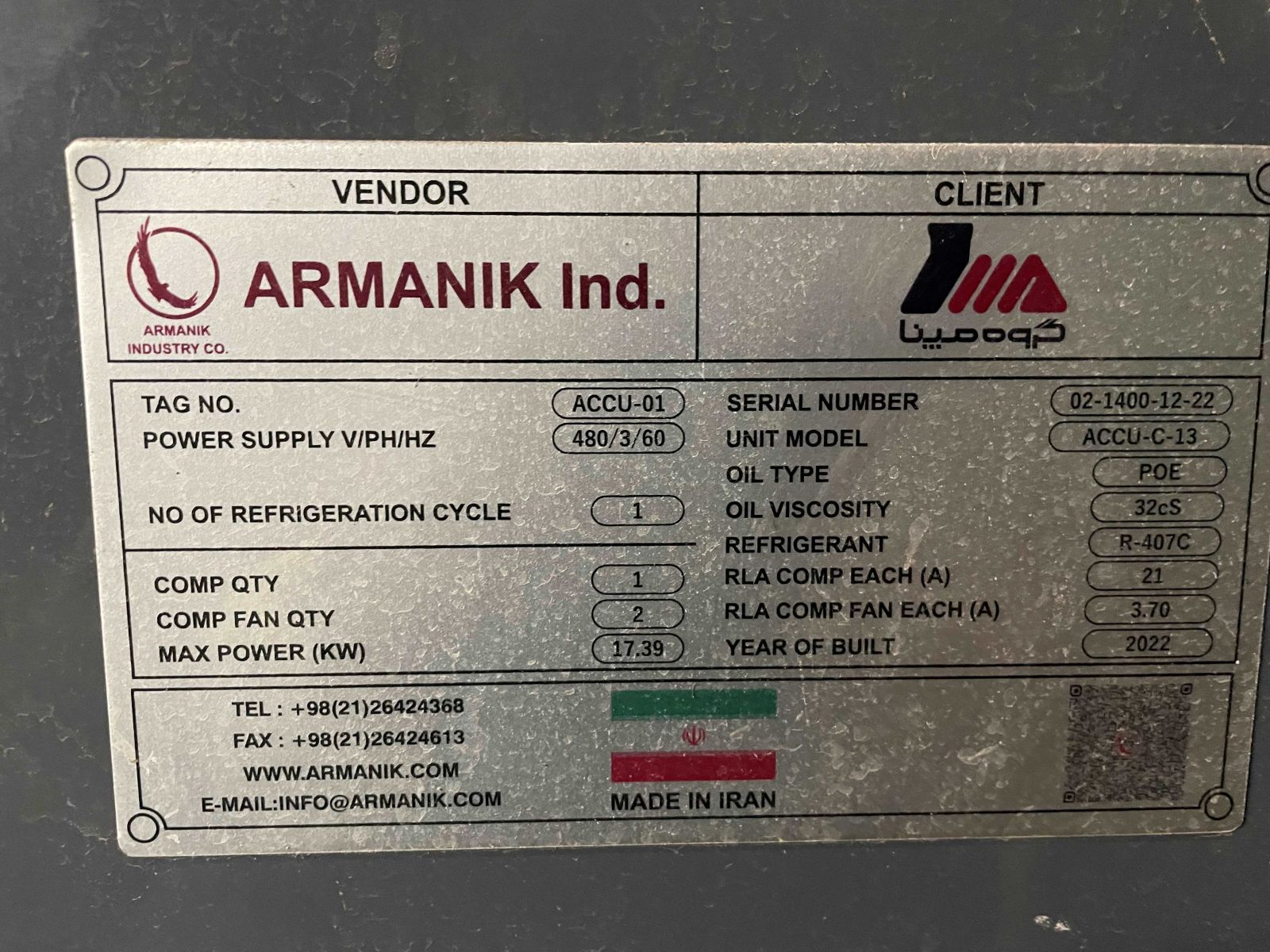

Phase 11 of South Pars gas field development field in the persian gulf is under reconstract and development and mapna MD-1 driilling rigs operated for rigging activities , ARMANIK was responsible for designing , producing ,installing , copper piping ,commissioning of a new condensing unit and air handling unit for galley and canteen area:

Challenges

Technical challenges (among other contractors)

Shock, vibration and EMC requirements

Vulnerability requirements for certain systems

Space constraints for the routing & handling and transporting of ACCU & AHU ,pipe-work and insulation.

Sound level restrictions

Incompatibility of new equipment and control system with some existing equipment

Complete the machine instrumental shortage

Loop-check

Time schedule limit

HSE regulations

Scope of work

ARMANIK’s scope of work for the above project comprised:

Pre-contract

Co-writing technical specifications ,site visit and general arrengement.

Post-contract

Complete followed by delivery, installation, commissioning, FAT, HAT, SAT,training activities.

System and process was constructed by MAPNA drilling co in tpersin gulf. .

Scope of suuply & service

1 x Air handling unit & condensing unit with heating , cooling & hyumidity control panel and monitoring

Among several smaller items of equipment, the following main services was supplied.

Site Visit, Check Foundations, AHU & ACU Visual Check, Find Out Piping & Cabling Route.

Design Interconnection Copper Pipe Size& Route For Liquid &Suction Line

Material Take Off Configuration Including Copper Pipe , Elbow ,Connectors, Support, Insulation,…

Hanging & Installation AHU units on Base Frame With Vibration Absorbers Pad

Reassembling Ahu's Section By Stiffeners

Hanging & Installation ACCU units on Base Frame With Vibration Absorbers Pad

Pipe Cutting , Fitting , Install Pipe Support ,Silver Brazing ,painting ,…. For Each Circuit .

Washing Circuits By Refrigerant R141-B

Nitrogen Pressure (Leak) Test for 24 to 48 hours According to the Site Specification And Remove Leakages

Install Insulation And Cladding.

Connect All Wires To Local & Control Panel And Instruments

Install All Instruments Such TT,HT,Pressure Transmitter ,Motorized Damper,...

Logic Test , Check Machine Inside Controllers & Switches.

Vacuuming ,Set The Core Driers , Change The Compressor Oil

Cleaning &Washing Machine Coils , All inside Equipment and Install AHU's Filters.

Charging refrigerant , Start-Up Circuits Separated And Partially.

Operation & Maintenance For 48 Hours Non Stop Working.

SAT activities

Check the acceptance criteria

Clients expert training

Performance Test